The Precision Backbone of Modern Metal Manufacturing

Introduction: Redefining Precision in Modern Manufacturing

In today’s fast-paced manufacturing world, efficiency, accuracy, and repeatability are critical. Among the most advanced and reliable manufacturing techniques available, the die casting process stands out as a cornerstone for producing complex metal components with exceptional precision.

Used extensively in automotive, aerospace, electronics, and industrial machinery, the die casting process enables the production of lightweight, durable, and dimensionally accurate parts in high volumes.

This blog explores the complete die casting process from mold design to finishing along with its benefits, applications, and emerging technological advancements that are shaping the future of precision metal manufacturing.

What Is the Die Casting Process?

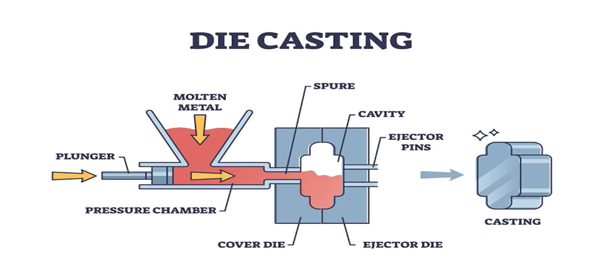

Die casting is a metal casting process in which molten metal is injected into a steel mold (die) under high pressure. Once the metal solidifies, the die opens, and the finished part is ejected.

This process is known for delivering tight tolerances, high production rates, and smooth surface finishes making it ideal for mass-producing intricate components.

Common metals used include:

- Aluminum – for lightweight, corrosion-resistant parts

- Zinc – for small, detailed components with excellent strength

- Magnesium – for high strength-to-weight applications

- Copper and Brass – for superior electrical and thermal conductivity

The Step-by-Step Die Casting Process

The die casting process involves a series of carefully controlled steps to ensure precision, consistency, and quality in every part produced.

1. Mold (Die) Design and Preparation

The process begins with designing a mold that matches the exact geometry of the desired component. Molds are typically made from hardened tool steel and consist of two halves — a fixed half and a movable half.

The mold is coated with a lubricant or release agent before each cycle to prevent the molten metal from sticking and to extend mold life.

🛠 CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) tools are widely used to simulate mold flow, predict defects, and ensure optimal mold performance before production begins.

2. Metal Melting

The selected metal alloy is melted in a furnace at a controlled temperature. The molten metal must maintain consistent viscosity and purity to ensure defect-free casting.

Temperature control is critical — too hot, and the die may wear prematurely; too cool, and incomplete filling can occur.

3. Injection Phase

Once molten metal reaches the correct temperature, it is injected into the mold cavity under high pressure (typically 1,500–30,000 psi).

This step ensures that the molten metal fills every intricate feature of the die, including thin walls and complex geometries.

There are two primary methods of injection:

- Hot-Chamber Die Casting: Used for low-melting-point metals like zinc and magnesium. The injection mechanism is submerged in molten metal, allowing faster cycles.

- Cold-Chamber Die Casting: Used for high-melting-point metals like aluminum and copper. The molten metal is ladled into a separate injection chamber before being forced into the die.

4. Cooling and Solidification

Once the molten metal is injected, it begins to cool and solidify inside the die. The cooling time varies depending on the metal type, casting thickness, and die temperature.

Uniform cooling is vital for maintaining part strength, dimensional accuracy, and surface integrity.

5. Mold Opening and Ejection

After solidification, the die halves open, and ejector pins push the solidified casting out of the mold. The casting is then moved to a trimming station for removal of excess material such as sprues and flash.

6. Trimming and Finishing

Trimming machines or robotic systems remove unwanted metal. Further finishing processes may include:

- Shot blasting or sandblasting – to clean the surface

- Machining – to achieve tight tolerances or threading

- Plating, painting, or anodizing – to enhance appearance or corrosion resistance

Finally, the part undergoes inspection and testing to ensure it meets dimensional and structural specifications.

Advantages of the Die Casting Process

The die casting process offers a powerful combination of speed, precision, and cost efficiency making it one of the most preferred methods for high-volume production.

1. High Dimensional Accuracy

Parts can be produced with tolerances as tight as ±0.002 inches, reducing the need for secondary machining.

2. Excellent Surface Finish

Components often require little to no finishing, with surface roughness values as low as 1–2 micrometers.

3. Lightweight and Strong Parts

Die cast components combine strength with minimal weight, ideal for automotive and aerospace applications.

4. Cost-Effective for Mass Production

Once tooling is developed, the process enables rapid cycles and low per-unit costs.

5. Design Flexibility

Capable of producing intricate, thin-walled shapes and complex geometries not feasible with other casting methods.

6. Material Recyclability

Excess metal and trim scrap are easily recycled, making die casting a sustainable manufacturing method.

Applications of the Die Casting Process

Because of its versatility and precision, die casting is used across a wide range of industries.

Automotive Industry

Used to manufacture lightweight parts such as engine blocks, transmission housings, and brackets improving fuel efficiency and performance.

Aerospace Industry

Provides strong, corrosion-resistant components for aircraft structures and mechanical assemblies.

Electronics

Ideal for enclosures, heat sinks, and connector housings due to excellent thermal conductivity.

Consumer Products

Used in appliances, power tools, and decorative hardware requiring smooth finishes and durability.

Industrial Equipment

Die cast parts serve in compressors, pumps, and machinery where precision and reliability are vital.

Modern Innovations in the Die Casting Process

The die casting industry is rapidly evolving with technological advancements that enhance efficiency, quality, and sustainability.

1. Simulation and AI Integration

AI-driven casting simulation software predicts flow behavior, cooling rates, and potential defects, optimizing mold design before production.

2. Automation and Robotics

Automated metal pouring, spraying, and part handling improve consistency, reduce labor costs, and enhance safety.

3. Vacuum Die Casting

Removes air from the mold cavity to minimize porosity and improve part strength and surface finish.

4. Sustainable Manufacturing

Advanced metal recycling systems and closed-loop cooling reduce environmental impact and energy consumption.

5. Additive Manufacturing for Tooling

3D printing is now used to create prototype molds or cores, accelerating the development process and lowering tooling costs.

Conclusion: The Future of Precision Lies in Die Casting

The die casting process continues to be a driving force in precision metal manufacturing. Its ability to produce complex, high-strength, and dimensionally accurate components combined with automation and sustainability innovations ensures its lasting relevance in global industries.

From automotive to aerospace, the process’s unmatched speed, consistency, and cost efficiency make it a preferred solution for manufacturers seeking both performance and precision.